Talk to us

08045801011

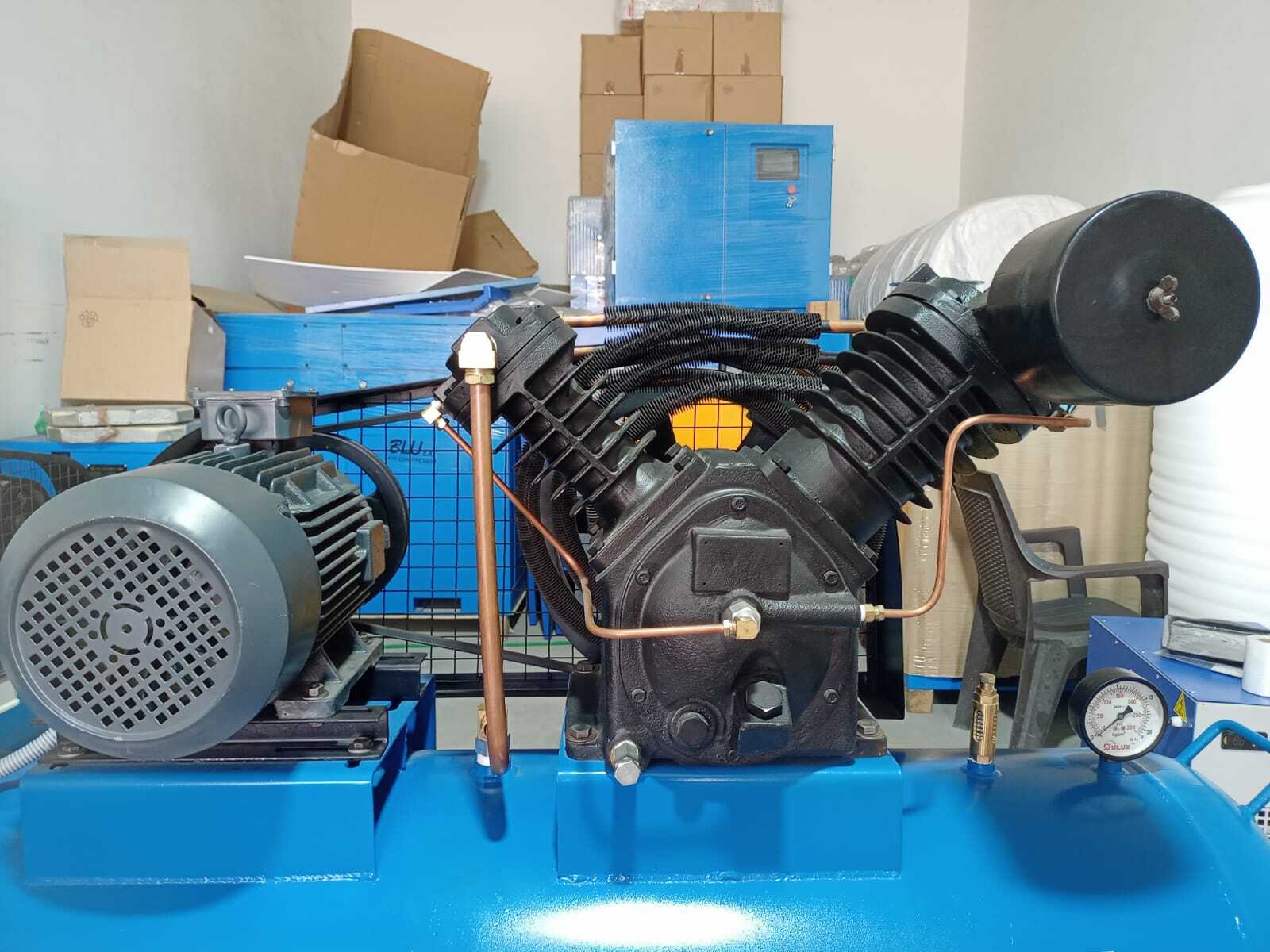

Reciprocating Air Compressor

Specification

|

Horse Power |

5 HP |

|

Brand |

KYROS |

|

Compressor Technology |

Reciprocating Compressor |

|

Compressor Brand |

KYROS |

|

Model Name/Number |

|

|

Maximum Flow Rate (CFM) |

17.5 |

|

Air Tank Capacity |

225 |

|

Power Source |

Electric DC |

|

Maximum Flow Rate |

0-20 cfm |

|

Cooling Method |

Air Cooled |

|

Rental Available |

Yes |

|

Spares Available |

Yes |

|

Is It Portable |

No |

|

Installation/After Sales Service Available |

Yes |

|

Warranty |

1 Year |

|

Motor |

Crompton Motor |

Price:

Price 512000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Driven Method : Star Delta

Product Type : Screw Air Compressor

Usage : Industrial

Price 299500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Driven Method : Star Delta

Product Type : Industrial

Usage : Industrial

Price 235000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 01

Driven Method : Star Delta

Product Type : Industrial

Usage : Industrial

Price 168500.00 INR / Number

Minimum Order Quantity : 1 Piece

Warranty : 1 Years

Driven Method : Star Delta

Product Type : Air Compressor

Usage : Industrial